Call us on

(+91) 77408 03329

E-mail us

bhagirathsteelandalloys@gmail.com

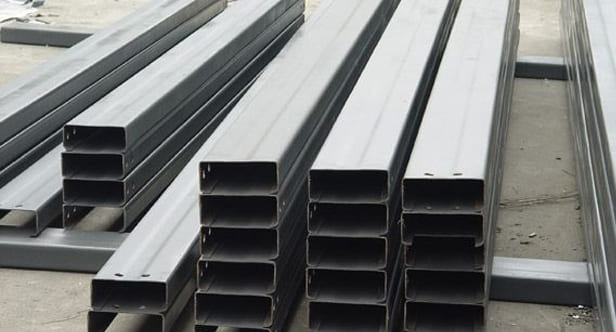

Channel Bar

As a leading stainless steel bar supplier in India, Bhagirath nSteel Alloy produce and manufacture different shapes of stainless steel channel bars

Factory Price

Top Quality

Custom Size

Description

Specifications

- Dimensions:

A. Delivery State: Hot Rolled: 40mmx80mmx4mm - 60mmx120mmx7mm B. Delivery State: Welded: 25mmx50mmx3mm - 100mmx280mmx12mm - Delivery State: Hot Rolled (Extruded), Welding(Laser Fused), Press Bending

- Finish: Pickled ,Bright, Polishing, Mirror, Hairline

- Tags: U Channel, C Channel, H Channel, I Beam, Profile

Standards

ASTM A276, ASTM A484M, DIN 1028, EN10056, GB4227

Features

Anti-corrosion (the degree is susceptible to the alloys contained), heat-resistance, good cold and hot working properties, good toughness, good comprehensive performances and wide application.

Applications

Home appliances, electric appliances, construction materials, medical equipment, auto parts, petroleum, chemical application, agricultural irrigation, edible oil refinery factories, paper plants, shipyard, nuclear power plant etc.

Manufacturing Process

Steel Making

Ingot Casting

Ingot

Round Bar

Heating

Hot Rolling

Heat Treatment

Cooling

Straightening

Skinning

Cold Drawing

Straightening

Polishing

Inspection

Analytic

Packing & Shipping

Drawing & Formula

Formula: m = [D × TW + 2 × TF × (B - TW) + 0.349 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793

* For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775

D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness,

R1 = Radius R1, R2 = Radius R2

Formula: m = [D × TW + 2 × TF × (B - TW) + 0.615 × (R1 × R1 - R2 × R2)] × L (m) × 0.0.00793

* For 316, 316L, 310S, 309S, etc., ratio=0.00798. For 400 series stainless steel, ratio=0.00775

D = Flange Depth, B = Flange Width, TW = Web Thickness, TF = Flange Thickness,

R1 = Radius R1, R2 = Radius R2